DYCROMINE DYES ON COTTON

1. INTRODUCTION

Jagson colorchem offers a wide range of DYCROMINE direct dyes for coloration cellulosic material. They are used for dyeing cotton, wool, silk viscose rayons, jute blends and union fabrics containing the cellulosic fibre using conventional equipment, for example becks, package dyeing machine winches, jigs and padding machines.

2. PREPATRATION OF GOODS

It is necessary to remove all impurities from grey yarn or fabric to ensure level dyeing, good penetration of dyestuffs and maximum brightness of the shade. Size may be removed by boiling the goods in alkaline detergent solution. in case of bleached good, it is advisable to wet the material with a suitable wetting agent, 0.75g/l, in hot and then it is rinsed in water.

3. DYEING METHODS

Two dyeing methods are recommended

Dyeing Method No.1

The dyebath is prepared using x% - Dyestuffs 0.5-2.0% - Soda ash and 5.0-30.0% - Calcined Glauber's salt or common salt. The dyeing is started at 50℃, the temperature is raised to 900 - 950 C. and the material is boiled for 45-60 minutes. The addition of salt should be made in gradual stages.

Dyeing Method No.2

Same as method no.1, but without addition of Soda ash. This method is generally used which is described as under.

-

A: X%

-

Dycromine dye

-

B: 1-8 g/l

-

Anhydrous Glauber's Salt

-

C: 4-32 g/l

-

Anhydrous Glauber's Salt

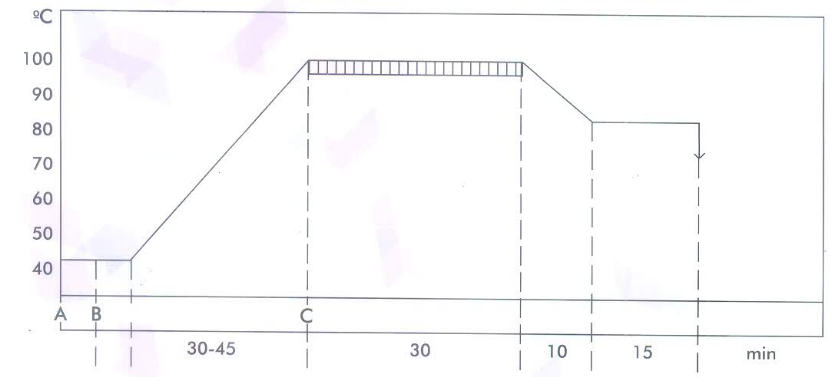

- Set the dyebath at 40℃ with required amount of water and dye.

- Run for 10 minutes and add anhydrous Glauber's Salt(B)

- Enter the goods and run for 10 minutes.

- Raise the temperature to boil within 30 to 45 minutes.

- Add anhydrous glauber's Salt (C) and continue the dyeing for 30 minutes.

- Decrease the temperature to 80℃ within 10 minutes and continue the dyeing for 15 minutes.

- Drain the dye bath and 70℃. give two cold washes and dry.

- If required, treatment of cationic dye fixing agent may be give to improve the fastness properties