Dycrosperse Disperse Dyes

Yellow SGF/Yellow 79

Yellow SG/Yellow 114

Yellow 4GLS/Yellow 211

Orange ERL/Orange 25

Yellow Brown 2RC/Yellow 30

Orange 3RFL/Orange 44

Scarlet BS 152/Scarlet 152

Scarlet GS/Scarlet 153

Rubine GFL/Rubine 73

Red S-BLF/Red 92

Red F3BS/Red 343

Red FBL/Red 60

Dark Red 2B/Red 167

Red Violet FBL/Red 26

Green SE6B/Green 9

Violet 3R/Violet 63

Violet/Violet 93

Brown 3R/Brown 1

Brown/Brown 4

Blue SE2R/Blue 183

Blue GSL/Blue 165

Blue BG/Blue 60

Blue FBL/Blue 56

Blue DBR/Blue 366

Blue 3G/Blue 79

Navy Blue EXNSF

Black RLS

Black EXSF

Black R

Black CCR

Luminous Disperse Dyes

Yellow 10GN/Yellow 184

Yellow 8GE/Yellow 82

Red G/Red 277

Red J

Pink RBSF/Pink 374

Pink 5BN/Pink 364

CN Pink

CN Violet

CN Blue

T. Blue GRXF

Blue SR/Blue 354

Acetate Disperse Dyes

Yellow G/Yellow 3

Orange GR/Orange 3

Red GG/Red 17

Red X3-B/Red 11

Pink GF

Scarlet 2G/Scarlet 1

Rubine GFL/Rubine 13

Magenta MGF

Violet RL/Violet 1

Purple H3-G/Purple 73

Blue FFR/Blue 3

Dark Brown 3BS

Black BT

Click here to see Dycrosperse Dye Process

Technical Shade Card

Comprehensive specifications and application methods for DYCROSPERSE Disperse Dyes

DYCROSPERSE

Introduction

Jagson disperse dyes can be used for dyeing and printing of polyester fibers and polyester fiber blends. In exhaust dyeing, the most important method of application is high temperature process.

Besides high temperature process Jagson disperse dye can also be used for carrier process and in continuous dying by the thermosol process. In printing fixation can be achieved depending on the sublimation properties either by HT steaming, hot air, or by pressure steaming. We have covered almost all the properties of disperse dyes in this shadecard. A lot of technical efforts have been taken to ease the implementation process of Jagson disperse dyes for the customers.

Dyestuff

Disperse dyes can be mainly divided in 3 basic structure:

- Azo

- Anthraquinone

- Special dyes

Respectively the dyes can be classified as:

| E-type | SE Type | S Type |

|---|---|---|

| Good leveling property | Good exhaustion type at medium dyeing temperature | Good for exhaustion at high dyeing temperature |

| Suitable for pale-medium shade | Good leveling property | Excellent sublimation and high stability for various finishing process |

| Suitable for carrier dyeing as well as high temperature dyeing | Good sublimation fastness | Suitable for medium-deep shade by high temperature,thermosol dyeing and printing |

| Suitable for pale-deep shade by high temperature,carrier,thermosol dyeing and printing |

Dyeing of Polyester Fibers

Polyester fibers have excellent properties in term of

- Strength

- Wear Resistance

- Resistance to chemicals

- Wash and wear properties

- Bulkiness

- Stretch properties

Following are the dyeing methods for polyester fiber:

- High Temperature

- Carrier

- Thermosol dyeing

- Thermosol printing

Practical dyeing methods, may vary according to kind of blended fibres, various fastness and handling to be required.

PRETREATMENT

The pretreatment and dyeing methods vary based on the form in which this substrate is being processed:

- Polyester loose material

- Tops, knit goods or woven fabric

- Spun polyester, filament, textured polyester filament

- 100% polyester fiber or blends

Pretreatment serves for removing sizes, preparations, and soil from the surface of the fiber. In case of knit and woven goods, it serves for relaxation and bulkiness.

In case of polyester-cellulose blends desizing and mercerizing must be carried out prior to scouring.

SCOURING

Desizing and scouring must be carried out prior to dyeing.

BLEACHING

Bleaching is an optional step. If a higher degree of white is desired, optical bleaching agents must be used.

HEAT SETTING

Heat setting is required to stabilize polyester fabric. Ensuring the piece goods retain its shape during all the stages depends on the nature and structure of the fabric.

pH VALUE of Dyes

pH needs to be maintained after all auxiliaries and dyes are added. Buffer system is used to maintain constant pH throughout the dyeing process.

DYEING

Disperse colors are usually high temperature dyes. In majority of the cases it is used in powder/ granule form. The 2nd option available is paste form which is 50%-80% content concentration of the powder product. Generally luke warm water (40° -50°C) is added with stirring to complete the dispersion .

HIGH TEMPERATURE DYEING

The dye batch must be controlled to pH 4.5-5 using weak acid such as acetic acid or with buffer using sodium acetate to promote the reproducibility of dyeing or to maintain the brilliance of shade.

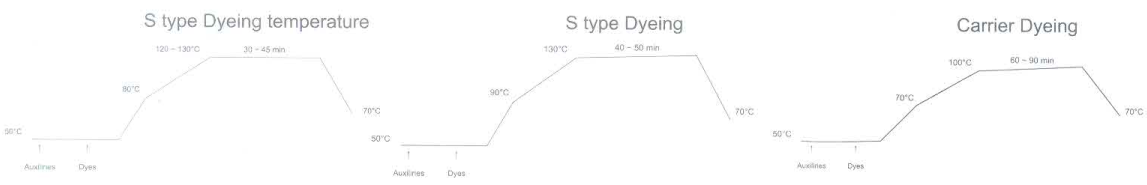

Dyeing Temperature Curves

Standard Recipe:

| Jagson Dyes | X% |

| Dispersing agent | 1 g/liter |

| Acetic Acid | to adjust pH 4.5-5.5 |

| Levelling agent |

CARRIER DYEING

Only selected dyes can be used in carrier dyeing because the exhaustion and build up property are rather poor. Compared to temperature dyeing covering property is also poor.

Standard Recipe:

| Carrier | Xg/liter |

| Jagson Dyes | Y% |

| Acetic acid | to adjust pH to 4.5-5 bring it to boil within 30-40 min |

| Dye | for 60-90

minutes according to depth of shade |

| And then Reduction clearing is done | |

•THERMOSOL DYEING

Thermosol dyeing is employed as a continuous dyeing mainly in polyester/cotton blends,because of very high fixing temperature around 200*C. Dyes with high sublimation fastness are recommended for the thermosol dyeing. Liquid grade dyes are recommended for thermosol dyeing

The stages involved in thermosol dyeing are: (Dyepad dyeing). It includes Reduction clearing after dyeing and washing.

For 100% polyester following process is followed:

THERMOSOL PRINTING

A)HIGH PRESSURE STEAMING METHOD:

RECIPE: for Color paste

| Jagson Dyes | X |

| Water | Y |

| Thickening paste | 500-700 |

| Tartaric acid/ Citric acid (pH 5-6) | 2-3 |

| Sodium Chlorate | 5 |

| Leveling agent | 10-20 |

| Total | 1000 |

| After printing and Drying, pressure is 20-30 min/ at 130°C then washed with cold and warm water followed by Reduction clearing process. | |

B)HIGH TEMPERATURE STEAMING (HT Steaming) DRY HEAT FIXATION

RECIPE: for Color paste

| Jagson Dyes | X |

| Water | Y |

| Thickening paste | 500-700 |

| Fixing accelerant | 50-80 |

| Tartaric acid/ Citric acid [pH 5-6] | 5 |

| Sodium Chlorate | 5 |

| Leveling agent | 10-20 |

| Total | 1000 |

| After printing and Drying, steaming 5-10 min/ at HT 170°C - 180°C then washed with cold and warm water followed by Reduction clearing process. | |

| Dyes | Xg/liter |

| Sodium Alginate (Migration Inhibitor) | 10-15g/liter |

| Wetting Agent | 1-2 g/liter |

| Acetic acid to adjust pH 5-6 | |

| Pad liquor temperature | 20°-30° |

| Pick up | 60-65% |

| Pre drying | To 25-30% Residual moisture |

| Drying Temperature | 110°-120° |

| Thermosol Temperature | 190°-210° |

| Thermosol Duration | 20-90 seconds |

Get Complete Shade Card

Download the complete PDF shade card with all technical specifications, color swatches, and application guidelines.

Download Shade CardPDF Format | Updated 2025