Dycrofix M

Cold Brand DCT type.

Yellow M8G/Yellow 86

CAS No.: 70865-29-1

Yellow M4G/Yellow 22

CAS No.: 12226-49-2

Yellow MGR/Yellow 7

CAS No.: 12226-46-9

Golden Yellow MR/Yellow 44

CAS No.: 112270-91-6

Yellow M3R/Orange 86

CAS No.: 83929-91-3

Yellow M4R/Orange 14

CAS No.: 12225-86-4

Orange M2R/Orange 4

CAS No.: 12225-82-0

Red M5B/Red 2

CAS No.: 17804-49-8

Red M8B/Red 11

CAS No.: 12226-08-3

Magenta MB/Violet 13

CAS No.: 12270-87-0

Violet C4R/Violet 12

Blue M2R/Blue 81

CAS No.: 75030-18-1

N Blue M3R

CAS No.: 12225-37-5

Blue MR/Blue 4

CAS No.: 13324-20-4

Customer Benefits

Economic range of cold brand dyes for room temp dyeing and printing

Application Method

Cold dyeing

Trichomy

Medium

Deep

Dycrofix HE

For Hot Exhaust economical dyes for standard requirements.

Yellow HE6G/Yellow 135

CAS No.: 77907-38-1

Yellow HE3G/Yellow 105

CAS No.: 176023-34-0

Yellow HE4G/Yellow 81

CAS No.: 59112-78-6

G. Yellow HE4R/Yellow 84

CAS No.: 61951-85-7

Orange HER/Orange 84

CAS No.: 91261-29-9

Red HE3B/Red 120

CAS No.: 61951-82-4

Red HE7B/Red 141

CAS No.: 61931-52-0

Red HE8B/Red 152

CAS No.: 71872-80-5

Navy Blue HER/Blue 171

CAS No.: 77907-32-5

Navy Blue HE2R/Blue 172

CAS No.: 85782-76-9

Blue HERD/Blue 160

CAS No.: 71872-76-9

Blue HEGN/Blue 198

Green HE4BD/Green 19A

CAS No.: 61931-49-5

Black HEBL

Customer Benefits

Suitable for post mercerizing

Suitable for post bleaching

Application Method

Hot Exhaust Economical Dyes

Trichomy

Pale

Medium Heavy

Supporting Dyes

Yellow HE6G

Yellow HE4G

Orange HER

Br. Blue HEGN 125

Dycrofix ME

For warm exhaust for normal fastness with good reproductivity.

Yellow ME4GL/Yellow 160A

CAS No.: 129898-77-7

G. Yellow MERL/Yellow 145

CAS No.: 93050-80-7

Orange ME2RL/Orange 122

CAS No.: 79809-27-1

Scarlet MEBL

Red ME3BL/Red 194

CAS No.:

Red ME4BL/Red 195

CAS No.: 93050-79-4

Red ME6BL/Red 196/250

Red MERBL/Red 198 A

CAS No.: 145017-98-7

Red ME3GL/Red 223

N. Blue ME2GL/Blue 194

N. Blue BRF/Blue 221

CAS No.: 93050-78-3

Blue BF/Blue 222

Blue ME2RL/Blue 248

Scarlet S2G/Red 222

Customer Benefits

More preferable because of better build up for dark shades

Good wash off properties for good fastness levels

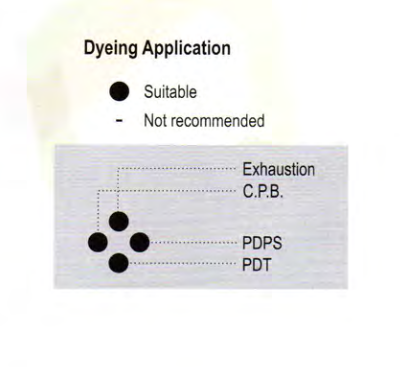

Application Method

Cold-pad-batch (Selectively)

Trichomy

Supporting Dyes

Yellow ME4GL

Orange ME2RL

Red ME3GL

Red ME3BL

Red ME6BL

Navy Blue ME2GL

Dycrofix VS

For warm exhaust and pad dying with excellent wet fastness.

Yellow FG/Yellow 42

CAS No.: 12226-63-0

Yellow GL/Yellow 37

Yellow GR/Yellow 15

CAS No.: 12226-47-0

G. Yellow RNL/Orange 107

Yellow H7GL/Yellow 57

G. Yellow R/Yellow 77

Orange 3R/Orange 16

CAS No.: 12225-88-6

Orange 3R/Orange 16A

Red C2G/Red 106

CAS No.: 105635-66-3

Red BB/Red 21

Red RB/Red 198

CAS No.: 93050-78-3

Red 5B/Red 35

Red F3B/Red 180

Violet 5R/Violet 5

CAS No.: 12226-38-9

Blue BB/Blue 220

Navy Blue RGB/Blue 250

N. Blue H2GLN/Blue 203

Brown GR/Brown 18

CAS No.: 12225-73-9

Blue RS/Blue 19

T. Blue G/Blue 21

CAS No.: 12236-86-1

Black RL/Black 31

CAS No.: 12731-63-4

Black B/Black 5

CAS No.: 12225-25-1

Customer Benefits

Various options available for black and navy in economic fastness

Good dischargeable shades for browns

Excellent wash off and fastness properties

Application Method

Cold-pad-batch

Pad-dry- chemical pad-steam (Selectively)

Pad-dry-steam (Selectively)

Pad-dry-thermofix (Selectively)

Trichomy

Supporting Dyes

Yellow H7GL

Yellow GL

Orange 2R

Red GF Red 5B

Brown GR

Violet 5R

Blue 3R

turquoise Blue PG

Green 6B

Navy Blue GG

Black RL

Black Dn conc

Black WNN

Dycrofix ED

Multifunctional warm exhaust for deep shades with cost effective and higher productivity.

Yellow ED-2G

Yellow ED

Orange ED2R

Red ED

Red ED-3B

Red ED-7B

Blue ED

Navy Blue ED

Black ED

Black EDG

Black EDR

Customer Benefits

Cost effective range with high productivity

Most preferable for deep shades

Good wash off and fastness properties

Resitant to wet fading and repeated domestic washing

Application Method

Cold-pad-batch

Pad-dry-chemical pad steam

Pad-dry-steam

Pad-dry-thermofix

Trichomy

Medium

Heavy Shades

Dycrofix S

Multifunctional warm exhaust high fixation eco-friendly with reliable applications.

Lemon S-3G

Yellow S-3R

Deep Orange S-4R

Deep Cherry S-D

Red S-B

Ruby S-3B

Ocean S-R

Dark Blue SGL

Deep Night S-R

Black S-N

Super Black G

Super Black R

Customer Benefits

Good multifunctional dyes with high fixation

Eco friendly with reliable applications

Application Method

Warm Exhaust

Trichomy

Dycrofix RGB

For warm exhaust and pad dyeing , economical for medium to dark shades.

Yellow RGB

Orange RGB

Red RGB

Deep Red RGB

Navy RGB

Deep Black RGB

Customer Benefits

Cost effective for medium shades

Cost effective for dark shades

Application Method

Warm exhaust and pad dyeing

Trichomy

Dycrofix Ultra RGB

Multifunctional warm exhaust and pad dyeing , economical for dark shades.

Ultra Yellow RGB

Ultra Orange RGB

Ultra Red RGB

Ultra Caramine RGB

Customer Benefits

Good multifunctional dyes for dark shades

Economical for dark shades

Application Method

Multifunctional warm exhaust and pad dyeing

Trichomy

Dycrofix SSX

High performance dyes for ultra deep shades for exhaust and pad dyeing.

Yellow SSX

Deep Orange SSX

Brilliant Red SSX

Deep Red SSX

Navy SSX

Black SSX

Customer Benefits

Simple process requiring minimal capital investment

Easy clean-down process suitable for short runs

Very high strength products

Excellent build-up for very deep shades

Good wash-off and fastness levels

Resistant to perborate wet fading

Resistant to repeated domestic washing

Application Method

Warm Exhaust

Pad-dry-chemical pad steam

Pad-dry-steam

Pad-dry-thermofix

Cold-pad-batch

Trichomy

For Very Deep Shades

Heavy Shades

Dycrofix LX

For warm exhaust suitable for pale shades with perfect reproducibility.

Yellow LX

Red LX

Red LX2B

Blue LX

Navy LX

Customer Benefits

Perfect Reproducibility

Application Method

Warm Exhaust

Trichomy

Pale

Medium Heavy

Dycrofix Blacks

For warm exhaust and pad dyeing high quality , high performance , economical & most suitable Blacks.

Black WNN

Black DN

Black CLS

Black GSP

Black HFGR

Black JNN

Black N150

Black XL

Ultra Black DN CONC.

Black NG

Black GWF

Black SJ

Dycrofix Eco

The most cost effective trichomy for exhaust dyeing.

Golden Yellow Eco

Red Eco

Navy Blue Eco

Dycrofix SE

It offers intense color strength, excellent washing fastness, and minimizes effluent discharge.

Gold SE

Orange SE

Brilliant Red SE

Deep Sea SE

Black SE

Customer Benefits

Warm Washing System: Rapid and effective dye removal while maintaining color fastness, with lower temperature operation saving water and energy.

Long-Lasting Color: Eco-friendly dyes meet ZDHC Level 3 standards, reducing resource use and supporting sustainable production.

Eco-Friendly Products: Certified safe manufacturing (ZDHC Level 3 & PCA/Pars Chloro Aniline Free) ensures environmental commitment.

Application Method

Easy Application: Works seamlessly on cotton and synthetic fibers at low liquor ratios, compatible with existing dyeing methods.

Environment-Friendly: Reduces resource consumption while supporting sustainable production; PCA/Pars Chloro Aniline Free certified.

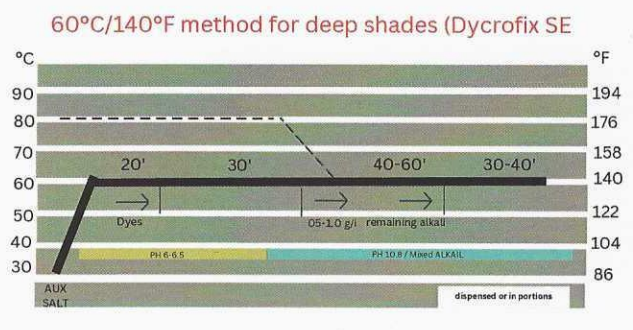

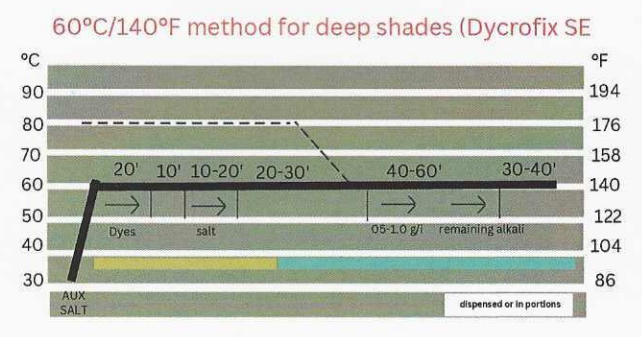

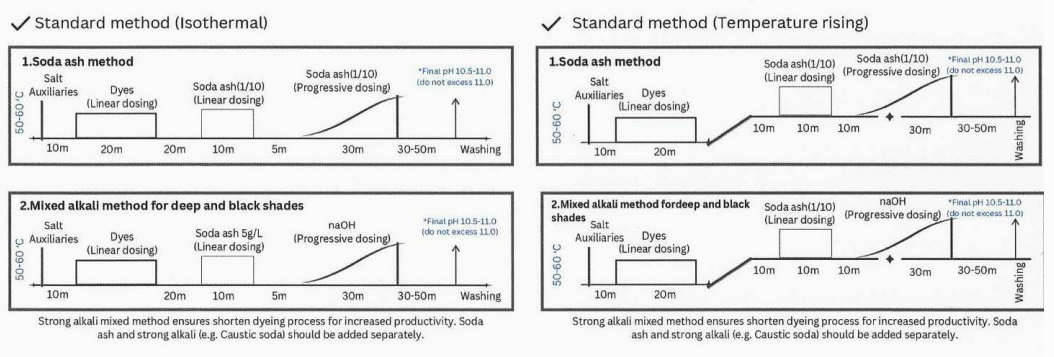

Alkali Addition Recommendations

Soda Ash Method:

1. portion, add 0.5-1.0 g/l of soda ash, progressively dispensed over 20-30 min

2. portion, add remaining quantity, progressively dispensed over 20-30 min

Mixed Alkali, Soda Ash/NaOH Method:

1. portion, add 0.5-1.0 g/l of soda ash, progressively dispensed over 20-30 min

2. portion, add remaining quantity of soda ash and caustic soda, progressively dispensed over 20-30 min

Sodium Bicarbonate / Soda Ash (for CV and CO merc. fabrics only):

1. portion, add 1.0 g/l sodium bicarbonate, linear dispensed over 10-15 mins

2. portion, add 1-2 g/l soda ash, linear or progressive dispensed over 20-30 mins

3. portion, add remaining soda ash, progressive dispensed over 20-30 mins

This method shows the best leveling performance on CV and Co merc. fabrics

Note: The recommended dyeing procedure is the 80°C/60°C migration method

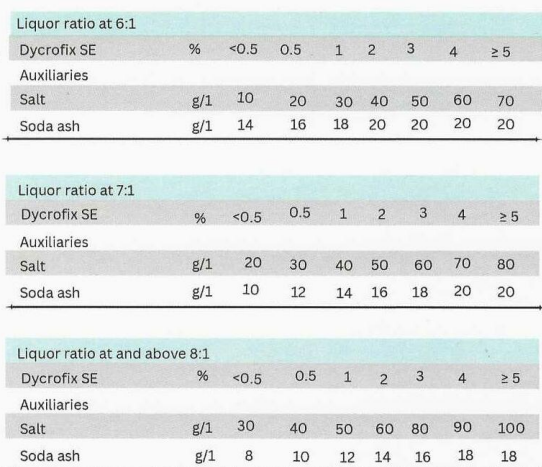

Salt & Alkali Recommendations at Different Liquor Ratios

Washing off 100% CEL

Washing-off, pale/medium shades (LR 1:6 and below):

• Rinse for 10 min at 60°C/140°F

• Rinse for 10 min at 60°C/140°F with 1-2 g/l Soaping Agent

• Rinse for 10 min at 60°C/140°F

• Soften as usual or aftertreat (Neutralization at pH 6-7)

Washing-off, dark/deep shade (LR 1:6 and below):

• Rinse for 10 min at 60°C/140°F

• Rinse for 10 min at 60°C/140°F with 1-2 g/l Soaping Agent

• Rinse for 10 min at 60°C/140°F

• Soften as usual or aftertreat (Neutralization at pH 6-7)

Notes on washing off:

No pH adjustment is necessary, pH should 10 to be expected after the first rinse. For thorough washing, the rinsing should be continued until the water remains colored. For efficiency and lower rinsing balls possible.

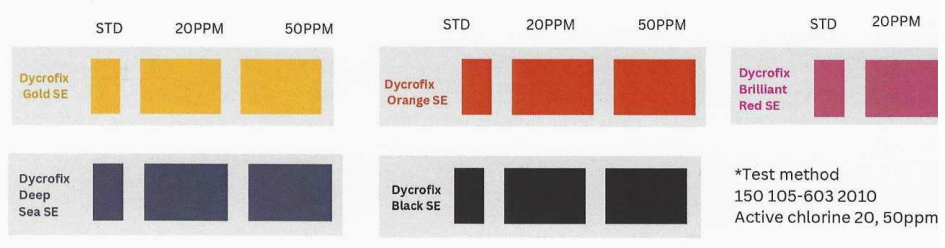

Fastness to Chlorinated Water

Stability to chlorine becomes much higher chlorinated water fastness ensures long lasting color quality required by current technical trends. These days, the consumer preference in all fields of textiles use is both for ease and wear and high wash fastness is color stability x and high in washable quality as well. The factor because chlorine is mostly used in tap water to make machine washable, and softening of colors used to be washed more frequently to achieve high color imports.

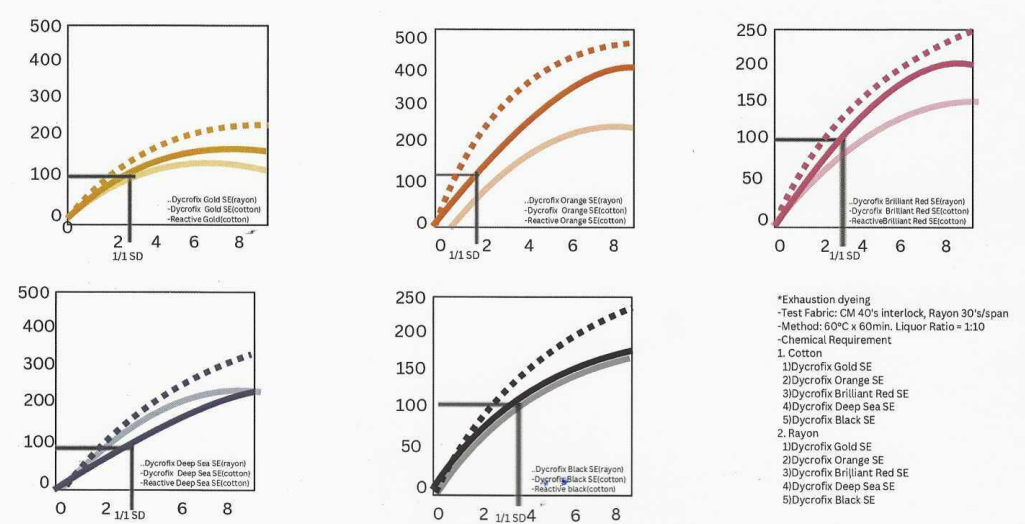

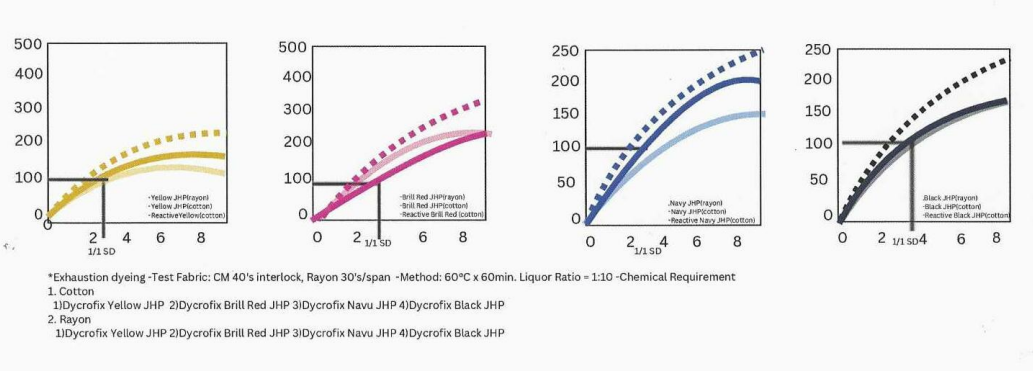

Build-up Property

Dycrofix SEdyes high color intensity results in lower dye and salt requirements, leding to the waem washing System.

Exhaust Dyeing Applications

60°C/140°F method for deep shades (Dycrofix SE):

Dyeing Methods for 100% CEL

60°C/140°F method for deep shades (Dycrofix SE):

Get Complete Shade Card

Download the complete PDF shade card with all technical specifications, color swatches, and application guidelines.

Download Shade CardPDF Format | Updated 2025

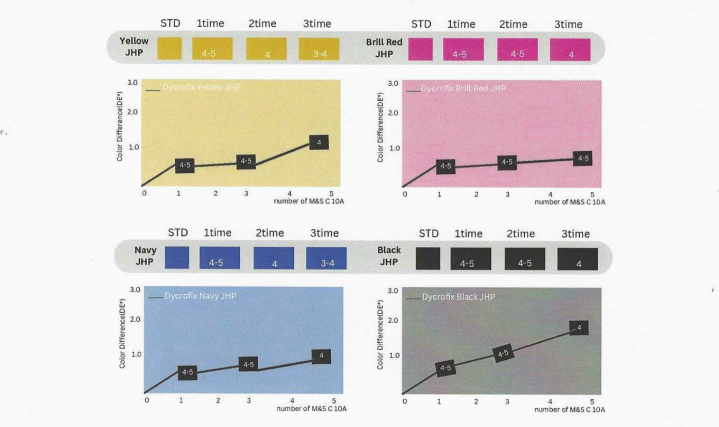

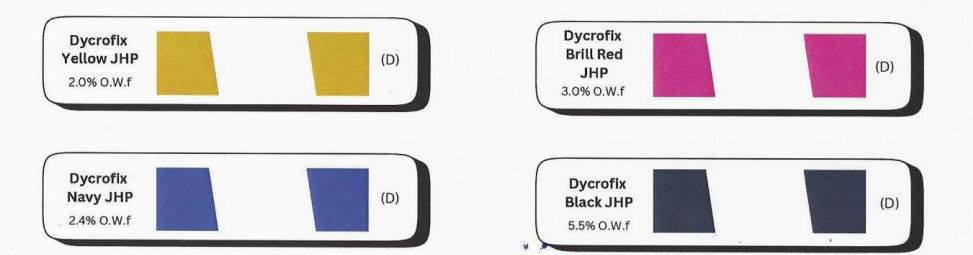

Dycrofix JHP

Redefines standards for deep shades in cotton dyeing and delivering intense color strength.

Yellow JHP

Brill Red JHP

Navy JHP

Black JHP

Customer Benefits

Improves production efficiency

Reducing water and energy consumption

Long lasting and intense color strength

Sustainable solution for modern textiles

Eco-Friendly and easy to implement

Application Method

Soda ash method

Mixed alkali method (for deep and black shades)

Efficient dyeing with warm washing technology

Dycrofix JHP Features/Advantages

A Sustainable Solution for Modern Textiles: Balances economic growth with environmental responsibility. Dycrofix JHP dyes enhance production efficiency while addressing key sustainability concerns, reducing water and energy consumption.

Unmatched Performance for Cotton Dyeing: Sets a new quality standard for deep shades with intense color strength and high wet fastness, delivering superior results from shorter processing times with improved productivity and environmental impact.

Efficient Dyeing with Warm Washing Technology: Ensures rapid and high exhaustion for cotton and cellulosic fibers. Warm Washing System simplifies removal of hydrolyzed dye, reducing water usage by up to 30% and cycle time by 25% while maintaining exceptional wet fastness.

Eco-Friendly and Easy to Implement: Meets rigorous environmental standards, including ZDHC Level 3 and eco-friendly certifications. Compatible with existing recipes and processes, ensuring smooth transition while maintaining vibrancy through multiple washes and supporting sustainability in fashion.

Long Lasting Colors

Dischargeability

Dischargeability varies with the depth of ground dyeing and recipe of white discharge. The discharge test was made on cotton fabrics dyed at the standard depth by the following recipes.

| Ingredient | % by Weight |

|---|---|

| Rongalite | 20% |

| Soda ash | 5% |

| Guar Gum | 1% |

| OBA | 0.1% |

| TOTAL | 100% |

Build-up Property

Dycrofix JHP dyes high color intensity results in lower dye and salt requirements, leding to the waem washing System.

Dyeing Process

The optional dyeing temperature is 50°C-60°C, but the appropriate dyeing temperature depends on the fabric types and dyeing machines.

Comments:

- For optimum color yield, less than final pH 11.0 is recommended to avoid excess hydrolysis.

- 50°C dyeing is possible for additional energy savings.

- Reproducibility is further improved at low liquid ratios dyeing.

- JHP dyes have high fixing ability; proper alkali dosing is a key factor to achieve the targeted dyeing result.

Get Complete Shade Card

Download the complete PDF shade card with all technical specifications, color swatches, and application guidelines.

Download Shade CardPDF Format | Updated 2025

Click here to see Reactive Dye Process

Reactive Dyes for Printing

Yellow P4G

Yellow P6G

G. Yellow PR

G. Yellow PGRN

Orange P2R

Orange P4R

Scarlet PRN

Red PBN

Red P2B

Red P4BN

Red P6B

Red P8B

Magenta PB

Purple P3R

Blue P5R

Blue P3R

Blue P2R

Tq. Blue PGR

Olive Green P2G

Brown P2R

Red Brown P4R

Black PN

Black PGR

Black P2R

Customer Benefits

Suitable for printing cellulosic fibers

Pad-dry-chemical pad steam

Pad-dry-steam

Pad-dry-thermofix

Application Method

Excellent reproducibility for high RFT levels

Good repeated domestic washing

High light fast selection available

Trichomy

Pale

Medium Heavy

Supporting Dyes

Orange P2R

Red PB

Red P6B

Red P8B

Purple P3R

Turquoise PGR 150

Red Brown P4R

Black PN

Black PGR

Pretreatment of the Goods

To ensure optimum results in reactive printing of woven or knitted fabric all impurities in the fibre, lubricants, auxiliaries and processing chemicals that could react with reactive dyes or adversely affect the printing process must be removed To obtain maximum colour yield brilliancy levelness and wet fastness properties on cotton, it has been mercerized or treated with a caustic soda solution of at least 22 °Be (16.4%) Regenerated cellulosic fibres should be treated in a tensionless state with a caustic soda solution of approx 6-8 °Be (4-5%) Alkaline pretreatment improves further dimensional stability and facilitates washing-off of the prints.

Stock Thickener

Sodium alginate: 400-600 Parts | Urea: 100-200 Parts | Dycrosol (Resist Salt): 10 Parts | KBl Liquid: 5 Parts | Sodium Bicarbonate: 25-30 Parts | Preservative: 0.5-1.0 Parts | Water: 1000 Parts

Print Paste Preparation

Stock thickener: X Parts | Dycrofix P Dyes: Y Parts | Total: 1000 Parts. Sodium alginate is ideal thickener as it does not react with dyestuff and can be easily washed off.

Fixation Methods

| Fixation Medium | Substrate | Time (min) | Temperature | Alkali |

|---|---|---|---|---|

| Saturated Steam | WO/Silk | 10-20 | 102°C | Sodium Acetate |

| Saturated Steam | CO/CV | 8-12 | 102°C | Sodium Bicarbonate or Soda Ash |

| Hot Air | CO | 5 | 150°C | Sodium Bicarbonate or Soda Ash |

| Hot Air | PES/CO | 1 | 190-200 C | Sodium Bicarbonate or Soda Ash |

| Superheated Steam | PES/CO | 6-8 | 175 X | Sodium Bicarbonate or Soda Ash |

Note: Higher urea amounts recommended for certain fixation methods

Two-Phase Prints

First of all the dried prints are impregnated open-width and crease-free with an alkaline fixation liquor and after that fixed as per the available equipment.

A horizontal padder with steel/rubber roller arrangement has effective to apply the alkaline fixation liquor which should allow both face padding and immersion of the fabric, depending on its structure and weight. The padding roller which comes into contact with the printed side of the fabnc should be made of steel (S) and the nip roller should be covered with rubber(R).

Fixation Liquors - Electrolyte/Alkali

Fixation Liquors :

| Electrolyte / Alkali | Amount | Unit |

|---|---|---|

| Water | x | cm³ |

| Soda ash | 150 | g |

| Common salt | 100 | g |

| Potash | 80 | g |

| Caustic soda 32% | 50 | cm³ |

| Sodium silicate (Na₂O:SiO₂ 1:3.3) | 50 | cm³ |

| Total | 1,000 cm³ | |

| Sodium Silicate | Amount | Unit |

|---|---|---|

| a) Na₂O:SiO₂ 1:1.7-2.0 | 1,000 | cm³ |

| b) Na₂O:SiO₂ 1:3.3 | 1,000 | cm³ |

Fixation medium : superheated steam

Substrate : cotton, viscose

Time : 90 sec

Temperature : 125 °C

Washing-off

Washing-off occurs in two stages: first to remove thickeners, chemicals, unfixed dyes and auxiliaries; second to maximize fastness. Swell dry thickening, remove residual alkali, unfixed dyes and auxiliaries. Best results with spray washing, separated rinse baths, and rapid liquor exchange at 90-95°C. Cold water start is possible.

In two-phase methods, intensively spray to remove thickening, alkali, and unfixed dyes at 40°C. Then wash at 60-70°C and 90-95°C. Use soft water to prevent calcium alginate formation. Complete removal of unfixed and hydrolyzed dyes is essential. Higher temperatures accelerate dye diffusion and removal.

Get Complete Shade Card

Download the complete PDF shade card with all technical specifications, color swatches, and application guidelines.

Download Shade CardPDF Format | Updated 2025

Click here to see Printing Dye Process

Technical Shade Card

Comprehensive specifications and application methods for Dycrofix Reactive Dyes

DYCROFIX

Auxiliaries

Sequestering Agent: Sequestering agents are used to soften water and bond free heavy metal ions. Sequestering agents that do not remove the metals from reactive dye complex dyes should be used, as this can lead to uneven dyeing. Therefore EDTA based products are not suitable.

Antifoaming: During both the running of the goods in bath and thus reduce foaminess. Extremely dilute solutions should be dosed into the bath where possible.

Lubricant: Lubricant agent prevents crack marks and creases. It should have no adverse effect on dye liquor stability.

Dyeing Application Charts

Application Chart 1

Application Chart 2

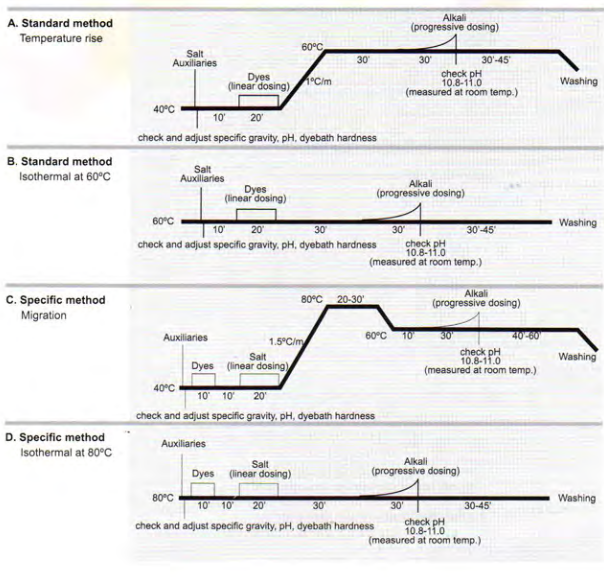

Dyeing Methods

Complete Dyeing Methods Chart

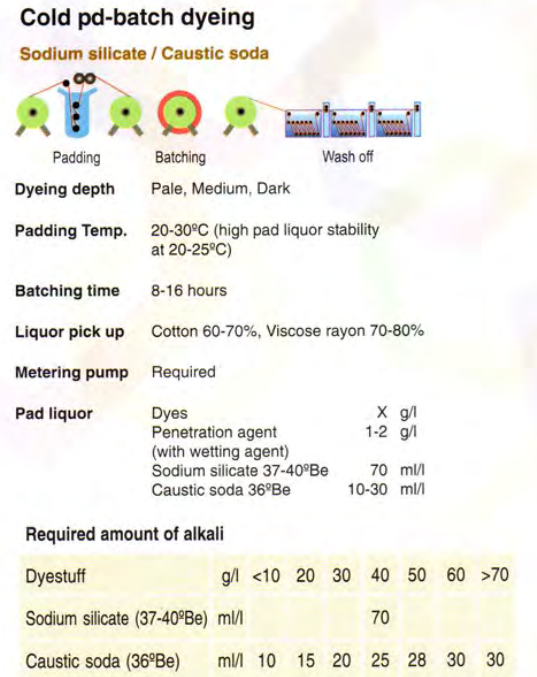

Cold Pad-Batch Method

- This method is the standard procedure for liquor temperature of 20-30°C.

- Short fixation time

- Metering pump required

- Good bath stability

- Atmospheric carbon dioxide has almost no effect during storage.

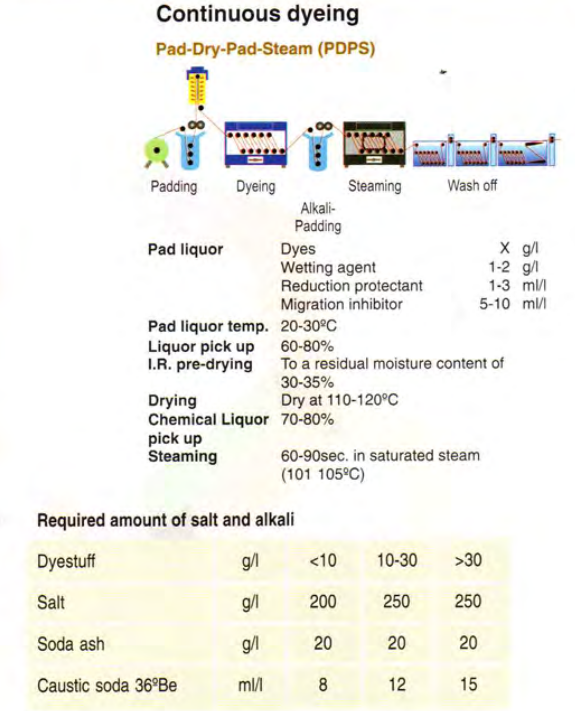

Continuous Dyeing Method

- High productivity and colour yield

- Good appearance

- Classic procedure for continuous dyeing of woven fabric

- When using dyes with low reactivity such as Dycrofix Turquoise Blue G the amount of caustic soda should be raised by 30%

- If the goods are stored, after drying but before fixation, they should be wrapped in an opaque material to protect them from daylight.

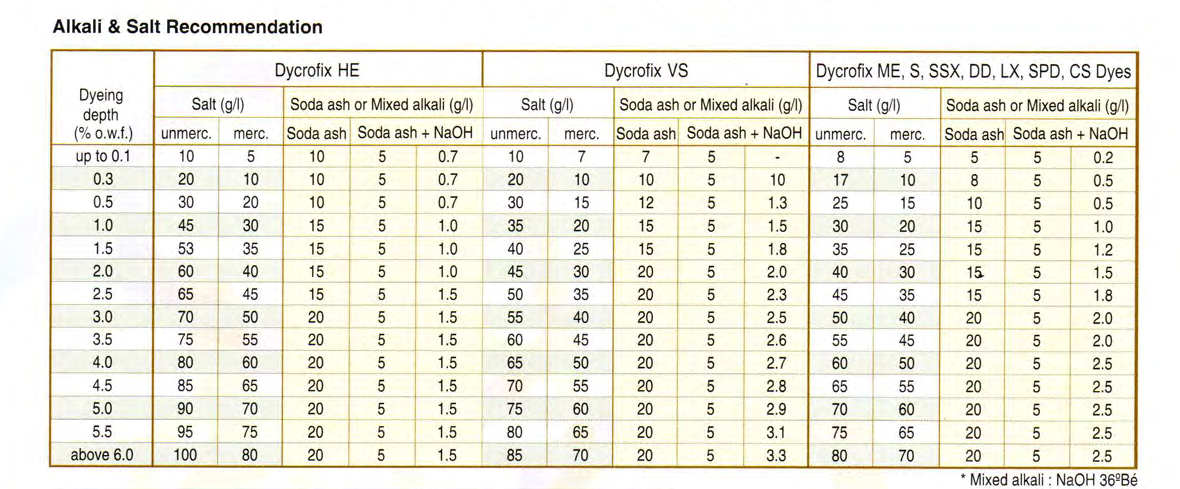

Exhaustion Dyeing

Salt

The same amount of common salt (NaCl) or Glauber's salt anhydrous (Na2SO4) can be used. If Glauber's salt cryst (Na2SO4 10H2O) is used, the amount of salt must be doubled.

Alkali

Caustic soda, soda ash can be used to fix the dyes. The type and amount of alkali required as stated in the below table. The final pH of Dycrofix reactive dye bath:

| Dyeing temperature | Final pH (30°C) |

|---|---|

| 50°C | approx. 11.0 |

| 60°C | approx. 10.5 |

| 80°C | approx. 9.5 |

Get Complete Shade Card

Download the complete PDF shade card with all technical specifications, color swatches, and application guidelines

Download Shade CardPDF Format | 2.5 MB | Updated 2023